During a past EPC project at a chemical plant site in Vietnam, a costly accident occurred: precision instrumentation equipment was damaged due to leakage current during welding operations. At first, we assumed it was a simple case of overcurrent. However, as we investigated further, we discovered that leakage current generated during welding was the root cause.

This was more than just an equipment failure — the damage led to delays in equipment procurement and nearly disrupted the commissioning schedule of the entire project. The incident even escalated into conflicts between departments, creating confusion and tension on site.

Since then, having experienced firsthand how invisible leakage current can lead to significant, unexpected accidents, I’ve been continuously sharing this case and educating workers on its risks.

.

.

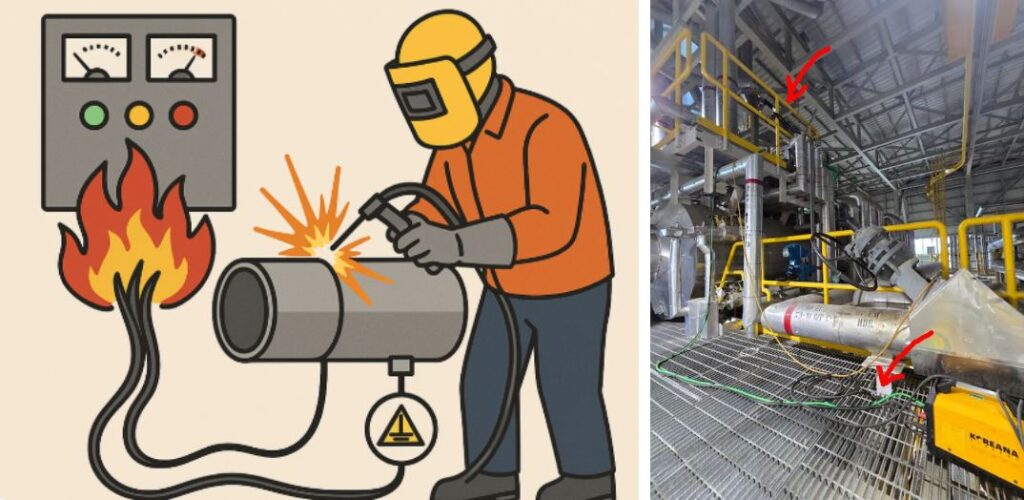

[Types of Fires That Can Occur During Welding]

Welding-related fires generally fall into three categories:

-

Fires caused by flying sparks (spatter)

-

Fires caused by Joule heat

-

Fires caused by electrical sparks

.

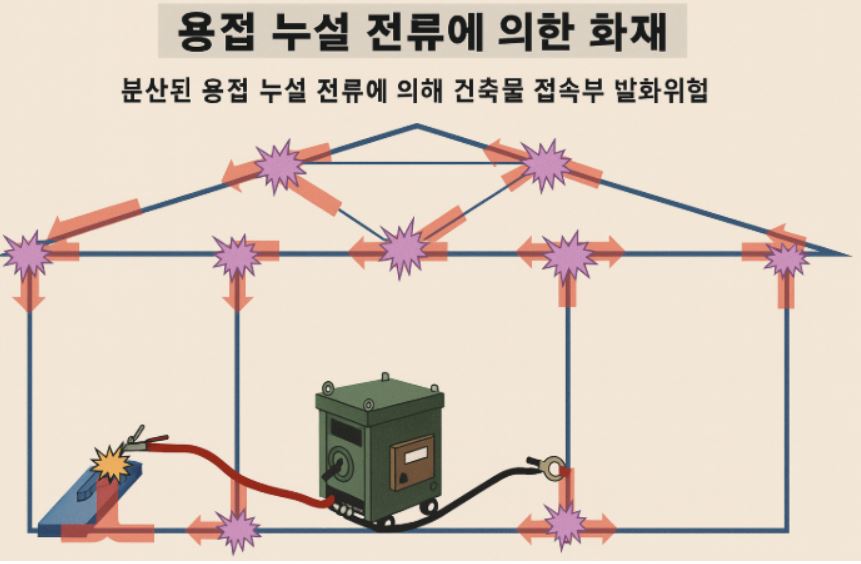

While flying sparks are visible and can be managed with measures like fire blankets, removal of flammables, and assigning fire watchers, fires caused by Joule heating and electrical sparks from leakage current are harder to detect and often overlooked. Worse still, when such fires occur, identifying the exact cause can be extremely difficult.

In particular, AC arc welders and DC inverter welders often do not have separate power switches. As soon as they are powered on, voltage is applied between the holder and the ground (earth). If leakage current occurs in this state, it can generate unintended heat or sparks in unexpected locations, leading to damage or fire.

.

.

[Why Is Leakage Current So Dangerous?]

Even when it doesn’t cause a fire, leakage current can still:

- Damage sensitive electrical and instrumentation equipment

- Occur far from the weld joint, making it hard to detect early

- Delay the entire construction schedule due to equipment reordering and procurement time

Ultimately, leakage current is an invisible but destructive risk that can have serious consequences if ignored..

.

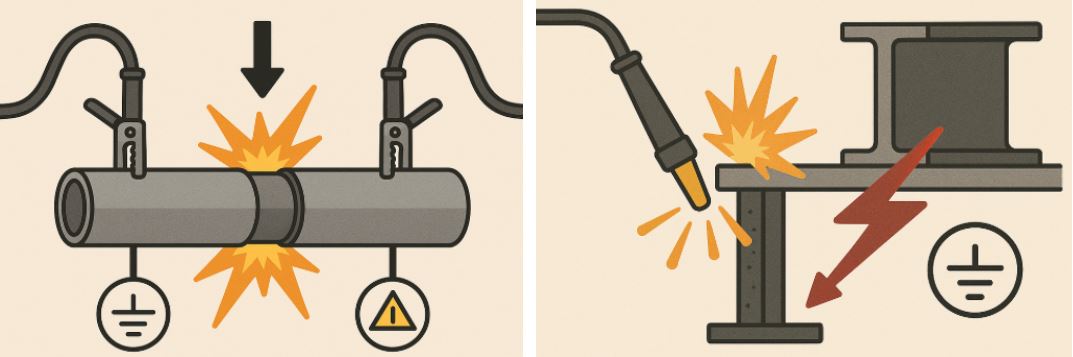

[Practical Preventive Measures Against Leakage Current]

Here are effective and field-applicable measures to prevent leakage current accidents:

-

Double grounding clamps on both sides of the weld joint

→ Creates equipotential grounding, blocking leakage current -

Minimize the distance between the weld joint and the ground

→ Reduces the potential range for leakage current -

Enhance electrical contact between the base metal and the ground

→ Use clamp-type, vise-type, or magnetic grounding tools effectively -

Insulate surrounding structures in contact with the base metal

→ Prevents unintended current paths -

Begin weld beads from the grounded side in pipe welding

→ Ensures a stable current flow and reduces leakage -

Ground the member side when welding onto pre-installed structures

→ Prevents formation of unintended current paths -

For magnetic large-diameter pipes, use magnetic switch-type grounding; for non-magnetic ones, use chain-type grounding

→ Keeps grounding close to the weld point, limiting leakage spread

.

[Conclusion]

Welding is often seen as “hot and spark-filled,” but the invisible flow of electricity is often the greater danger. Special attention is required when sensitive instrumentation or control systems are nearby..

It’s essential for workers, supervisors, and managers alike to fully understand the risk of leakage current and include the above preventive actions in their pre-task safety checks.

I hope this case can help improve safety at other worksites as well. Let us remember:

“An invisible current can be more frightening than visible fire.”