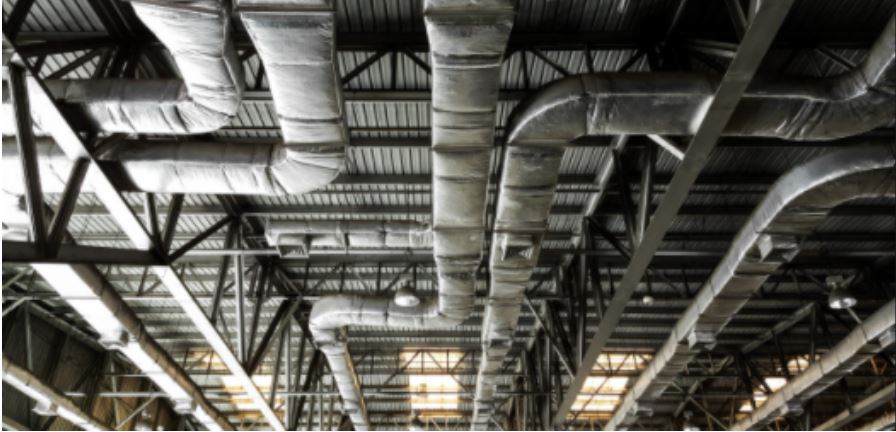

22. Maintenance Work on Plant

22. Maintenance Work on Plant plant maintenance is the application of best practices to increase equipment up time in manufacturing facilities. This helps plants avoid unplanned downtime and ensures production stays on schedule. ∴ Why is maintenance of plant and equipment important? An effective maintenance programme will make plant and equipment more reliable. Fewer breakdowns will […]

22. Maintenance Work on Plant 더 읽기"