▣ Classification of Piping System Stresses

-

Primary Stress

-

Stress induced by forces and moments applied internally and externally to the piping system, including bending stress from internal pressure, self-weight, wind, and other factors, as well as torsional stress.

-

The safety of primary stress is evaluated by comparing it with the allowable stress of the piping material.

-

-

Secondary Stress

-

Stress caused by thermal expansion due to the temperature of the fluid flowing through the pipeline. Even if this stress exceeds the yield strength of the material, it can enter a safe stress range due to stress relaxation.

-

Unlike primary stress, secondary stress is not compared directly with the allowable stress but rather with the allowable stress range to determine safety.

-

-

Allowable Stress

-

The stress level that a material can safely withstand under various temperature conditions concerning primary stress.

-

These values are provided in the ANSI Code.

-

.

.

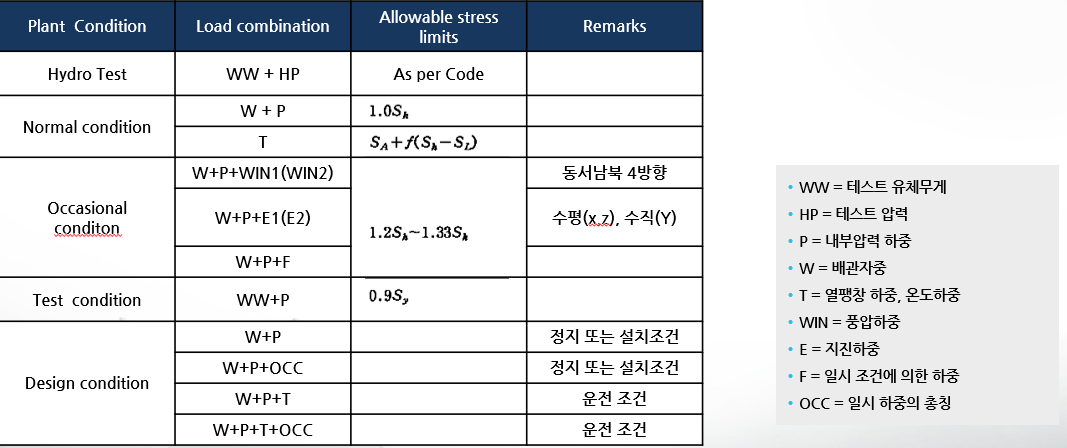

▣ Types of Stresses

-

SI: Longitudinal Stress

-

Sc: Circumferential Stress

-

Sr: Radial Stress

-

Ss: Shear or Torsional Stress

.

▣ Static Stress Analysis

-

Sustained Load: Includes dead weight and internal pressure.

-

Occasional Load: Includes wind load and seismic load.

-

Support: Analysis of self-weight, hydrodynamic pressure, and reaction forces.

-

Evaluation of Impact on Connected Equipment Due to Forces & Moments:

-

Includes rotating machinery such as pumps, compressors, turbines, and air fin coolers.

-

Evaluates nozzle load stress for vessel nozzles (cylindrical, spherical) and heaters.

-

-

Stiffness Ring Design for Vacuum Lines.

-

Underground Stress Analysis: Includes thermal and earth pressure design.

-

Branch Reinforced Pad Design.

.

▣ Dynamic Stress Analysis

-

Safety Valve Thrust Calculation.

-

Vibration: Includes considerations for reciprocating compressors and two-phase flow.

-

Seismic Analysis: Includes static method and response spectrum method.

-

Surge Analysis: Involves determining energy absorption devices due to sudden pressure rises in long-distance high-speed fluid pipelines, caused by rapid valve switching or power outages.

.

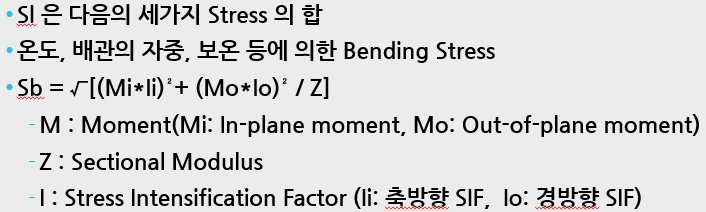

▣ Flexibility Analysis of Piping

-

Flexibility analysis involves reviewing whether the piping between fixed points has adequate flexibility to accommodate thermal expansion, ensuring that pipe supports are designed to withstand sustained and occasional loads.

-

The flexibility analysis is performed to ensure the proper layout of the piping, and it typically does not require a special calculation procedure or the creation of a calculation report as part of the piping stress analysis documentation.

-

It is not necessary to perform flexibility analysis for every piping system.

Cases Where Analysis is Not Required (ASME B31.1):

-

The installed piping system is identical to a system with proven usage or is a replacement for such a system.

-

The installed piping system is judged to be adequate when compared to a previously stress-analyzed system.

-

The installed piping system has a constant diameter, no restraints between two anchors, and the total number of operating cycles is 7,000 or less, satisfying specific equations.

.

▣ Piping Stress Analysis Codes

-

API675: Positive Displacement Pumps Controlled Volume

-

API-618: Reciprocating Compressors For General Refinery Services

-

NEMA SM23: Steam Turbine For Mechanical Drive Service

-

API-560: Fired Heaters For General Refinery Services

-

API-610: Centrifugal Pumps For General Refinery Service

-

API-611: General-Purpose Steam Turbines For Refinery Service

-

API-612: Special-Purpose Steam Turbine For Refinery Service

-

API-617: Centrifugal Compressors For General Refinery Service

-

API-661: Air-Cooled Heat Exchangers For General Refinery Service

-

API-650: Welded Steel Tanks for Oil Storage

-

API-1102: Liquid Petroleum Pipelines Crossing Railroads and Highways

-

ANSI A58.1: Minimum Design Loads For Buildings and Other Structures

-

ANSI B31.3: Chemical Plant and Petroleum Refinery Piping

.

▣ Stress Analysis Report

-

After performing stress analysis, document the results and retain them for reference.

-

Includes applied codes, computer programs, and general information.

-

Assumptions applied in the design.

-

Hold Item Lists.

-

Isometric Drawings used for piping stress analysis (including input data).

-

Computer input data (design conditions, material properties).

-

Basis for thermal expansion displacement calculations for equipment.

-

Review of nozzle loads based on load combinations.

-

Load Summary Sheets for anchors and supports based on load combinations.

-

Computer-generated results, etc.

-

.

▣ Review Items After Analysis of Self-Weight, Occasional Load, and Thermal Expansion

-

Is the sag of the piping due to self-weight within acceptable limits?

-

Are the loads on equipment nozzles within allowable limits?

-

Is the maximum stress within the allowable stress?

-

Are excessive loads generated on the designed anchors?

-

Is there an upward load (Up-Lift Load) due to the load?

-

Does the thermal expansion displacement cause interference with nearby piping?

-

Are there lower points than the drain point due to thermal expansion?

-

Are the analysis results within allowable limits for each operating mode?

.

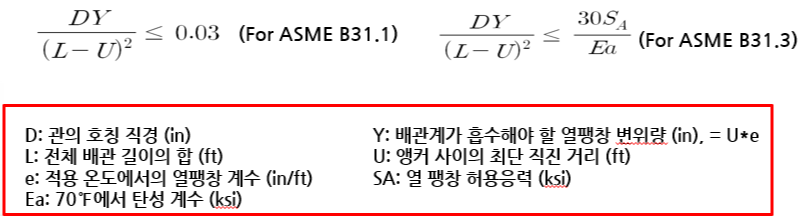

▣ Load Combinations and Allowable Stress

-

Design Condition:

-

Considerations include the piping’s self-weight (including the weight of the fluid, insulation, concentrated loads such as valves), design pressure, seismic load, etc.

-

-

Normal Operating Condition During System Operation:

-

Includes piping self-weight, internal pressure, thermal expansion load, and abnormal conditions that may occur during operation.

-

Includes dynamic loads, internal pressure, and thermal expansion loads.

-

-

Test Condition:

-

Testing considerations.

-

.

▣ Load Combinations (ASME B31.1)

.

▣ Coordination with Other Disciplines

DisciplineMain Coordination Tasks

No. |

Description |

Structural |

– Transfer of dead load and anchor load, thermal load transmission– Verification of seismic and wind load design criteria |

Civil |

– Transfer of foundation load for independent supports– Receipt of seismic and wind load design criteria |

Equipment |

– Transfer of nozzle load (Force & Moment) results– For general vessel nozzles, verification of analysis results by equipment design personnel– For high-temperature, high-pressure vessels, verification by equipment design personnel or manufacturer |

Mechanical |

– Request for verification of rotating equipment nozzle loads– Confirmation of nozzle integrity by mechanical personnel or manufacturer |