1. Purpose

This guide aims to establish safety requirements for the use of hand-operated tools

.

.

2. Scope of Application

This guide applies to all tasks in industrial workplaces where hand tools operated by human force are used.

.

.

.

3. Definitions

(1) The terms used in this guide are defined as follows:

(a) Driver

A hand tool mainly used to tighten or loosen small screws, wood screws, or tapping screws. It is commonly referred to as a screwdriver.

(b) Plier

A hand tool used mainly to grip, bend, or cut copper wires or steel wires.

(c) Spanner

A round-ended or open-ended hand tool used to assemble or disassemble bolts, nuts, or screws.

(d) Knife

A tool used to cut materials such as paper.

(e) Files

Hand tools mainly used for manual finishing or shaping of metal.

(f) Saw

A metal-blade tool used for manual cutting work.

(g) Scissors

General-purpose scissors used for cutting and trimming.

(h) Hammer

A hand hammer used for metalworking, woodworking, and earthwork tasks.

(i) Chisel

A hand tool used mainly to shape or cut metal or wood, including chisels for metalworking and woodworking.

(j) Punches

Hand tools with sharp or shaped ends used to make holes of various forms.

(k) Wrench

A hand tool used to tighten or loosen bolts, nuts, or screws, including adjustable wrenches and pipe wrenches.

(l) Pliers

Hand tools with adjustable jaws for gripping objects of various sizes, equipped with cutting edges for wire, and used for bending or fixing tasks.

(m) Clamp

A hand tool used to temporarily secure a workpiece firmly in one position to facilitate woodworking, welding, or metalworking. Compared to a vise, it is generally lighter and easier to use.

(n) Vises

Hand tools attached to a workbench to hold a workpiece securely during manual finishing or assembly work.

.

.

.

4. Hazard Factors

4.1 General Hazard Factors

-

Loss of balance leading to falls or overturning while using a hammer at elevated locations

-

Hammer heads flying off during use due to loose, cracked, or split handles

-

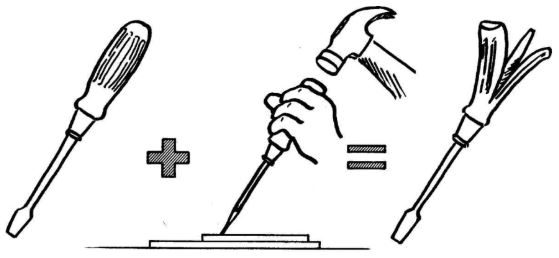

Using hand tools for purposes other than their intended design, such as using a chisel as a screwdriver

-

Flying workpieces or fragments, or rebound when removing product binding bands

-

Tripping over hand tools left in walkways due to poor housekeeping, or being struck by tools falling from above

.

.

4.2 Hazard Factors by Hand Tool Type

4.2.1 Driver

-

Worn, bent, dull, or damaged tips; broken handles; chipped ends

-

Using as a substitute for chisels or punches, operating with one hand while holding an object with the other, or using drivers of improper size

4.2.2 Plier

-

Dull gripping surfaces or worn handles

-

Use of improper shapes or use for unintended purposes

4.2.3 Spanner

-

Broken or worn jaws, mechanical defects, or damaged handles

-

Using spanners of improper shape or size, extending handles with pipes, or using as a hammer

4.2.4 Knife

-

Dull blades or worn handles

-

Leaving knives in hazardous locations or failing to use a sheath

4.2.5 File

-

Missing handles or clogged or dull file surfaces

-

Using as a punch or striking with a hammer

4.2.6 Saw

-

Dull blades or loose handles

-

Incorrect use of blade orientation or using only part of the blade length

4.2.7 Scissors

-

Applying force with feet instead of hands when cutting

-

Cutting excessively thick or heavy metal beyond the tool’s capacity

4.2.8 Hammer

-

Loose or detached handles, or improperly seated hammer heads

-

Using inappropriate hammer types or placing hands directly below the striking point

4.2.9 Chisel and Punch

-

Damaged heads or excessively shortened ends that are difficult to grip

-

Failure to maintain tools in proper working condition

4.2.10 Wrench

-

Damaged adjustment screws or worn or missing teeth

-

Using improper shapes or sizes, or extending handles with pipes

4.2.11 Pliers

-

Using pliers as a substitute for hammers or other tools

-

Cutting hardened wire or bending rigid steel wire

4.2.12 Clamp

-

Using pliers, pipes, hammers, or pliers instead of dedicated tools for tightening

-

Using clamps for long-term fixation instead of temporary holding

4.2.13 Vise

-

Striking the handle with a hammer to apply excessive tightening force

-

Repairing a vise by welding or soldering

.

.

.

5. Actions Before Using Tools

-

Select appropriate tools and sizes considering task type, material characteristics, and worker strength

-

Conduct repeated education and training to ensure proper use

-

Install protective barriers and wear safety goggles or face protection where flying fragments may occur

-

Install work platforms or wear safety harnesses for elevated work

-

Inspect handle fastening and check for wear or deformation before use

-

Remove oil or contaminants from handles and confirm tool condition prior to use

.

.

.

6. Safety Measures by Tool Type

6.1 Assembly Tools

(Wrenches, Drivers, Pliers, etc.)

-

Ensure jaws fit properly to prevent slipping; do not insert wedges into wrench openings

-

Do not extend handles with pipes or strike tools with hammers

-

Choose tools with sufficient handle spacing to prevent finger pinching

-

Pull tools rather than pushing them during operation

-

Use dedicated wrenches instead of pliers for nuts and bolts

-

Prevent excessive heat exposure

-

Apply lubricant regularly to pivot points

-

Use driver tips that match slot width and length

-

Do not use rounded or worn driver tips

-

Use drivers with straight alignment; do not modify mismatched tips

-

Use insulated drivers for electrical work

-

Use magnetic drivers in hard-to-reach areas

-

Do not hold screws with the other hand while using a driver

.

.

6.2 Cutting Tools

(Knives, Saws, Scissors, Chisels, etc.)

-

Perform cutting vertically and shield surrounding areas to prevent flying materials

-

Maintain safe distances and restrict access when removing binding bands

-

Never cut toward your body

-

Check for nails, knots, or foreign objects before sawing

-

Start cutting slowly and apply pressure only on the downward stroke

-

Use scissors only for soft metals

-

Direct debris away from the body depending on handedness

-

Adjust nuts and bolts properly and lubricate regularly

-

Use wooden or plastic mallets for chisels

-

Inspect materials for foreign objects before work

-

Use whetstones—not powered grinders—to correct heat-treated chisels

-

Do not use chisels with mushroomed or damaged ends

.

.

6.3 Striking Tools

(Hammers, etc.)

-

Install work platforms and wear safety harnesses in fall-risk areas

-

Use clamps or fixtures to support workpieces during two-person tasks

-

Select hammer heads larger than the striking surface

-

Maintain stable posture and relax muscles before heavy hammering

-

Use appropriately weighted hammers and test before full use

-

Avoid gripping handles with oily hands; use anti-slip gloves

-

Exercise extra caution in confined or unstable footing conditions

-

Do not strike hard objects that may cause fragments to fly

-

Discard cracked or loose handles and secure them properly

-

Strike vertically and focus on the target area

-

Replace hammers with cracks, chips, deformation, or excessive wear

.

.

.

6.4 Fixing Tools

(Clamps, Vises, etc.)

-

Do not use for lifting materials or assembling scaffolding

-

Do not forcibly fix workpieces using auxiliary tools

-

Select clamps based on:

-

Strength and weight

-

Ease of adjustment

-

Surface gripping condition

-

Material type and size

-

-

Secure vises firmly to workbenches using all bolt holes

-

Use sufficiently large vises to avoid deforming workpieces

-

Do not extend vise handles to apply excessive force

.

.

7. Safety Rules

7.1 General Requirements

-

Employers must provide safe hand tools, and workers must maintain them properly

-

Take appropriate measures to protect nearby workers from flying materials

Sharp blades must be kept in suitable condition; dull blades are more dangerous -

Wear personal protective equipment such as safety goggles, gloves, and face shields

-

In flammable environments, avoid steel striking tools; use brass, plastic, aluminum, or wooden tools instead

.

.

7.2 Safety Rules

-

Use hand tools suitable for the task

-

Maintain tools in proper working condition

-

Store tools in safe locations

-

Do not throw tools

-

Do not use damaged tools

-

Inspect tools before use

-

Do not climb ladders while holding tools

-

Ensure hands are not holding tools unnecessarily during work

-

Do not use tools for unintended purposes

-

Tag unusable tools and do not use them until repaired

-

Prevent tools from falling onto other workers

-

Assign responsibility for tool maintenance and report defects immediately

-

Protect sharp tools appropriately

-

Store tools in designated storage after use

-

Do not carry sharp tools in clothing pockets

-

Record and manage all hand tools to ensure safe and normal use at all times

.

.