▣ Standards Applied in Piping Design Calculations

1) Piping

- Power Piping ANSI/ASME B31.1

- Process Piping ANSI/ASME B31.3

- Flanges ANSI, B16.5

2) Pressure Vessels

- Unfired ASME, Sect. I & VIII, Div.1

- Unfired Steam Boilers ASME, Sect. I

- Fired Steam Boilers ASME, Sect. I

3) Safety Relief Systems

- Safety Valves API RP520 and API RP521

- Header ASME, Sect. I and VIII

4) Pumps

- Centrifugal API 610

- Reciprocating API 674

5) Compressors

- Centrifugal API 617

- Reciprocating API 618

- Air Compressor (Centrifugal) API 672

6) Steam Turbines API Std 611 & 612

7) Exchangers ASME Section VIII & TEMA

8) Flammable and Combustible Liquid Storge NFPA Volume 1

9) Foam Extinguishing Systems NFPA Volume 7

10) Storage Tanks

- Atmospheric Pressure API Std 620, 650, 2000

.

.

.

.

▣ ASME B31.1 – 2001 – Power Piping

-

Application: Piping for industrial plants and marine applications.

-

Requirements: Prescribes minimum requirements for design, materials, fabrication, erection, testing, and inspection of power and auxiliary service piping systems for central and district heating plants, power-generating stations, and other facilities.

-

Pressure: Applies to external piping for power boilers generating steam at pressures greater than 15 PSIG and to hot water boilers operating at pressures exceeding 160 PSIG or 250°F.

.

▣ ASME B31.2 – 1986 – Fuel Gas Piping

-

Status: Replaced by ANSI / NFPA Z223.1 but still valid for use within ASME.

- Use: Considered a reference standard for the design of gas piping systems.

.

▣ ASME B31.3 – 2002 – Process Piping

-

Application: Applied to process piping in chemical and petroleum refineries.

-

Coverage: Codes for processing and refining hydrocarbons, water, steam, chemicals, and other fluids, including rules for materials and components, design, fabrication, assembly, examination, and testing.

-

Usage: Used in chemical plants, pharmaceutical plants, textile, paper, semiconductor, cryogenic plants, and related facilities, and generally applicable to petrochemical plants.

.

▣ ASME B31.4 – 2002 – Pipeline Transportation Systems for Liquid Hydrocarbons and Other Liquids

-

Application: Applies to the design, materials, fabrication, assembly, erection, examination, inspection, and testing of piping transporting liquids such as crude oil, condensate, gasoline, LNG, LPG, CO2, alcohol, and anhydrous ammonia.

- Facilities: Used in natural gas plants, tank farms, terminals, ammonia plants, and other facilities.

.

.

.

.

▣ ASME B31.5 – 2001 – Refrigeration Piping and Heat Transfer Components

-

Application: Covers requirements for heat transfer components, refrigerant inspection, and auxiliary (cooling water) piping for cryogenic services.

-

Exclusions: Does not apply to water piping or pressure vessels and piping under 15 PSI (105kPa) for non-critical systems.

.

▣ ASME B31.8 – 2003 – Gas Transmission and Distribution Piping Systems

-

Application: Covers testing of pipeline facilities used for the transportation of gas.

- Coverage: Includes operational and maintenance safety of the system.

.

▣ ASME B31.8S – Integrity Management System for Gas Pipelines

-

Application: Applies to gas pipelines and related systems transporting gas.

-

Approach: Provides principles and processes for implementing an integrated management program for pipeline system integrity using proven practices and processes.

.

▣ ASME B31.9 – 1996 – Building Services Piping

-

Application: Regulations for piping systems in industrial, commercial, and public buildings that do not require the size, pressure, or temperature criteria of B31.1.

-

Coverage: Prescribes requirements for design, materials, fabrication, assembly, erection, inspection, and testing of piping systems.

.

▣ ASME B31.11 – 2002 – Slurry Transportation Piping Systems

- Application: Specifies design, construction, inspection, and security requirements for slurry piping systems.

.

.

.

.

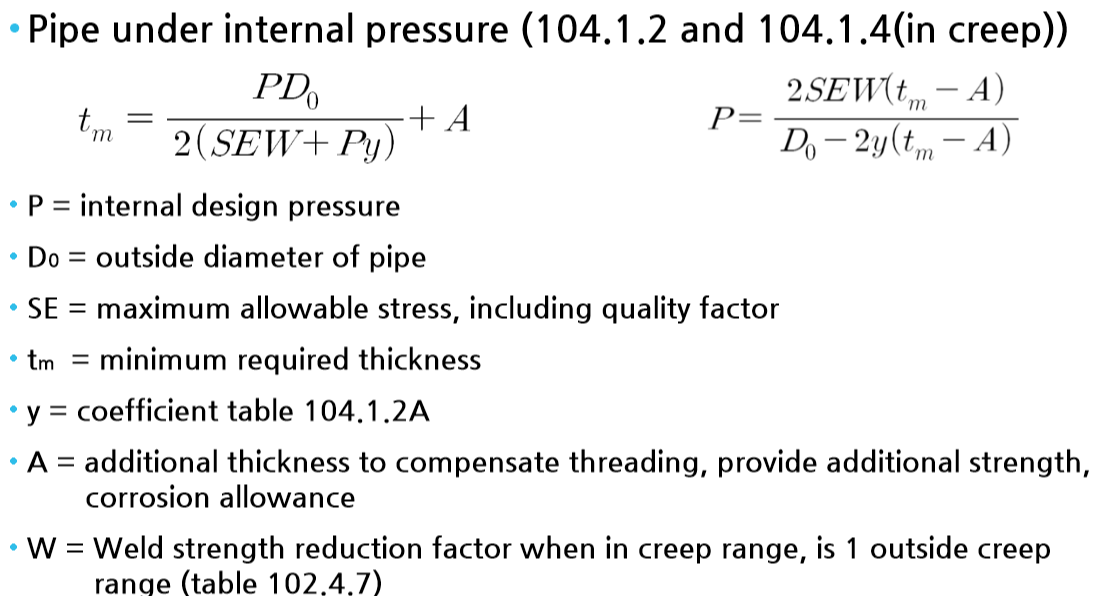

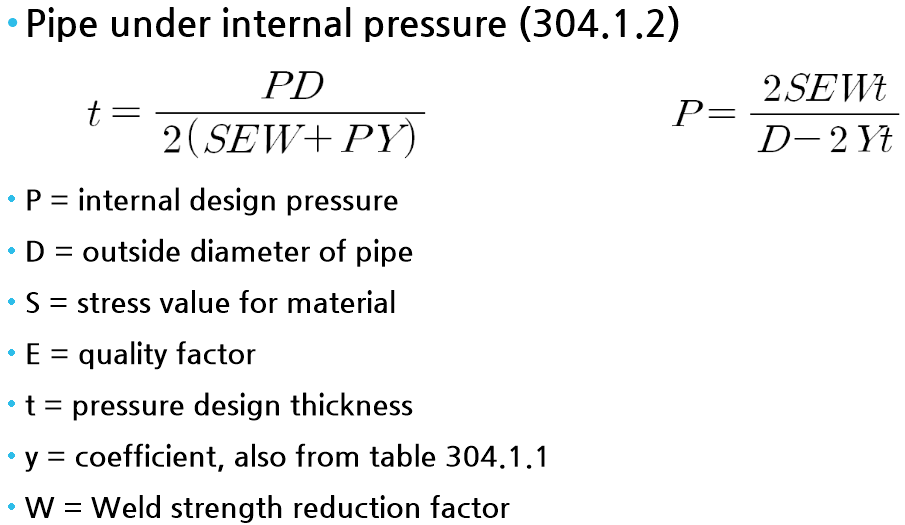

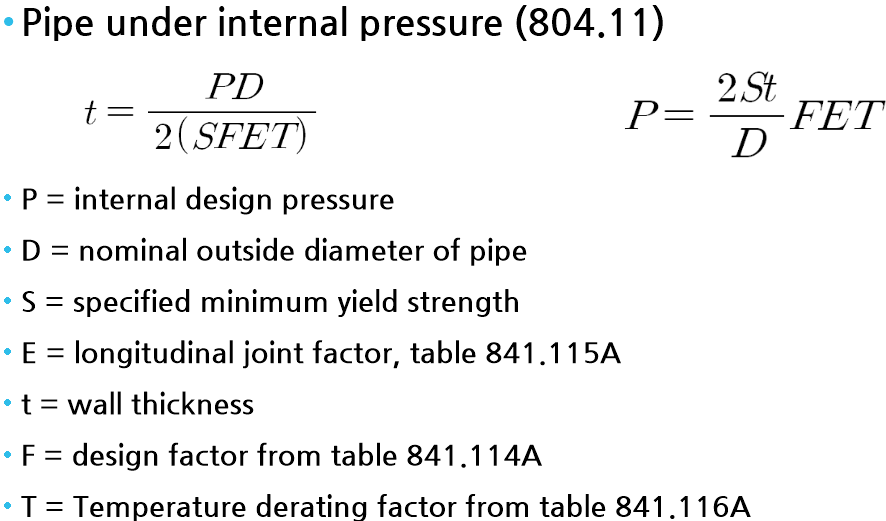

[ Differences in Calculation Methods by Design Code ]

▣ ASME B31.X Calculation Differences

▣ Power Piping B31.1

.

.

▣ Process Piping B31.3

.

.

▣ Gas Transmission Piping B31.8

.

.