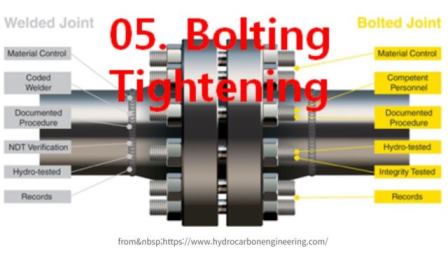

05. Bolt Tightening and Torquing

[General Information]

Bolts may seem simple, but in reality the proper manufacturing of bolted joints requires careful study. Tightening the bolt puts the shank in tension, counteracted by compressive forces on the contact surfaces of the head and the nut, transferred from the parts. Inadequate preload is a common cause for bolted joint failure, which is why it’s so important to use the appropriate bolt tightening methods.

∴

60여개가 넘는 작업단위별로 구분된 JSA를 갖고, 향후 위험성평가에 조합하여 사용하시면 접근이 쉽지 않을까 싶습니다. 아래 JSA는 단순하게 철골작업시 볼팅작업을 떠올려 보시면 쉽게 이해가 되실겁니다.

볼팅 작업은 의외로 단순하지만 힘이 많이 들고, 기술도 필요합니다. 적절한 볼팅이 이뤄지지 않고 너무 많이 힘이 들어가면, 모터, 배관 등의 연결부위가 파손되어 긴급자재 구매가 필요한 경우가 종종 발생되기 때문입니다.

구경이 큰 볼트의 경우, 렌치/스패너 등에 파이프를 임의로 추가 연결하여 조이다가 공구가 뛰어나가 주위 근로자를 타격하여 골절상 등이 발생하기도 합니다. 참고하세요.

∴

∴

| Hazard Category | Hazards | Controls |

| Physical Injury | 1. Can cuase by falling or flying object

2. Toe or feet crushed by falling or heavy pointed object 3. Hand injury from pinch point cut by rough surfaces or sharp objects 4. Eyes injury by flying particles, spark and dust |

1. All personnel working at site must wear PPE (Personnel Protectice Equipment),

2. Personnel involved directly with bolt tifhtening/ torquing must wear right kind of gloves, ear plug and face shield. 3. All employees working at height 1.8 meter (6 feet) or above must wear full body harness with double lanyard and must connect to the anchorage point all the time |

| Materials Fall or Seroius Injury | 1. Cause by use of tools or machine without inspection

2. Cause by use of tools or machine damaged 3. Failure of access for unauthorized person |

1. Supervisor shall inspect the air compressor for any air, water, fuel and oil leak or any defect

2. Not use the compressor damaged until repair 3. Ensure that the air compressor is grounded properly 4. The air hose couples holes are sealed with wire and locked and whiplash are provided to air out let and air hose 5. Employees directly involved with bolting/ torquing activities must wear air plug and combination of safety glasses and face shield. 6. Barricade and stand by man (hole watcher) shall be assigned to insure person can no access area 7. Critical activities shall be stopped as per HSE Standard during sand storm, rain and bad weather |

| Sips and Trips | 1. Can occur pool housekeeping

2. Failure of preservation of access or walkway due to improper materials storage |

1. All ways and access shall be free of equipment and materials that would create a tripping hazard for personnel using the access

2. Receptacles for watst materials shall be provided at site and regular clean-ups shall be conducted. 3. Employees shall be housekeeping at least 15 minutes before work finished daily 4. Supervisor shall appoint storage area at the site. |

∴