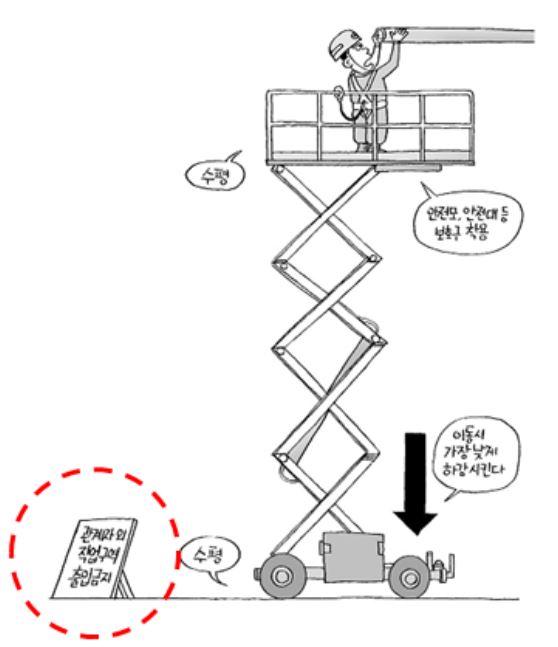

25. Moving Around Platform

고소작업대, 컨베이어, 자동화창고 등의 AGV (Automated Guided Vehicles) 등등 주변에 움직이는 기기 또는 장치가 있는 환경에서 작업이 이뤄지는 상황을 전제로 위험요인을 파악하고 있습니다.

입동이 지나고 2021년 첫 겨울비가 내리는 날이네요. 몸은 춥겠지만, 마음은 따뜻한 겨울이 되었으면 좋겠네요.

∴

∴

| Hazard Category | Hazards | Controls |

| Hearing Damage | 1. During maintenance works, etc. There are many hazards present which could cause personnel to slip or trip such as trailing cables, hoses, spilage of oil or grease or waste and debris | 1. Personnel shall remain vigilant while moving around the platfrom and report and make sure any hazards which they observe.

2. Spillages shall be cleaned up immediately using absorbentmaterials and any slippery surfaces cleaned and degreased. 3. Supervisors shall monitor the standards of housekeeping during routime walk arounds and implement clean up when necessary. |

| Striking Objects | 1. Due to the position of proess plant and equipment on an offshore platfrom. Thers are not always defined access ways to all areas of work. There are many objects which may protrude from process pipe work and equipment such as valves, sight glasses and guases, etc. | 1. Any mobile plant and/or equipment which is taken onto the platform shall be stored in a safe manner and out of access/egress routes.

2. Red & white shall be used to highlight any objects which protrude into access/egree routes or other areas where personnel are like to walk |

| Foreign Bodies in Eyes | 1. Airborne particules and debris are common features of major offshore construction and maintenance activities. Although dust blow into an individual’s eye may only cause temporary discomfort, particles propelled from grinders, etc. can cause more serious injuries | 1. Organization operates a eye protection poliy on all project locations. This policy is strict and shall be adhered to at all times.

2. Personnel shall wear the correct eye protection for the task in hand, i.e. goggles, when handling chemicals. 3. Supervisors shall monitor the workforce to ensure that they are wearing the correct type of PPE |

| Restricted Access/Egress Routes | 1. Accidents can occur (Especially during emergencies) when access/egress routes are blocked or restricked by plant, equipment, tools or trailing cables and hoses, etc. | 1. Access/egress routes shall be kept clear at all times during construction and maintenance works. Where this is not possible alternative acess/egress routes shall be provided and all personnel advise of the alternative arrangements.

2. Supervisors shall monitor acess/egress routes to ensure that they are kept clear |

| Falls of Tools and Equipment | 1. Serious injuries can occur when items of plat, tools and equipment have not been secured during work activities | 1. All items of plant, tools and equipment shall be positioned in a safe secure manner.

2. Supervisors shall monitor the position of all plant and equipment to ensure that it is safe and secure. |

| Lack of information and Emergency Procedures | 1. Acidents can occur if personnel are not given adequate information oon job requirements or emergency procedures | 1. PErsonnel shall be given enough information to enable them to carry out their duties in a safe and sufficient manner (especially on emergency procedures).

2. Toolbox talks shall be carried out to ensure all personnel made aware of their responsibilities. 3. Personnel shall contact their immediate supervisor if they require more information or are not sure of their responsibilities. |

| Adverse Weather Conditions | 1. Due to its location an offshore platform offers little protection against adverse weather conditions | 1. Suitable and sufficient personal protective equipment (PPE) shall be worn to protect against any possible adverse weather conditions.

2. Personnel shall not arry out any tasks (during adverse weather conditions) that could have a significant impact on their health and safety, i.e. welding in water, etc. |

감사합니다.