27. Operating Bench Type Profile Cutters

Ensure bench type profile cutters are securely fastened to a bench or purpose-designed stand.

Ensure shearing edges are in good condition, distortion free and correctly adjusted.

Ensure working parts are well lubricated and the blades free of rust and dirt.

Check workspaces and walkways to ensure no slip/trip hazards are present.

∴

∴

| Hazard Category | Hazards | Controls |

| Eye Injuries | 1. Can occur when sparks are ejected during the initial cut or when the cutting tip cuts through an inferior area of plate.

2. At all timee, it must be remembered that ‘The eye is not only irreplaceable, but also the sofest point of entry to the brain’ |

1. Organization operates a mandatory eye protection plilcy, eye protection shall be worn at all times.

2. Operators shall wear full face shields (anti-flash) when operating the profile cutters |

| Explosive atmosphere created by fuel/oxyjen leakage | 1. This is possible the most serious of the risks presented by the profile cutters and will ocur if adequate inspection and maintenance produres are not in place | 1. Fuel and oxygen hoses, fittings and attachments shall be regularly inspected and peridically leak tested

2. All gas hoses shall be puirged after use and gas cylinders isolated 3. All cutting tips and cylinders shall be fitted with flash-back arresters and hose check valves to prevent a blow back to the cylinder |

| Explosion | 1. This is a common effect caused by watching the cutting head when in operation | 1. Anti-flash face shields shall be worn when operating profile cutters

2. Organization operates a mandatory eye protection policy 3. Safety glasses shall be worn by all other personnel at all times 4. Eye injuries shall be treated immediately by a first aider |

| Fire and Explosions | 1. Potential fire hazards must always be eliminated especially when in the proximity of highly explosive atmospheres

2. These can occur if waste materials, debris and drawings are allowed to accummulate around the profiles |

1. All combustible materials shall be disposed of (in the scrap bins provided) after use to reduce any possibilities of fire

2. Fire extinguishers shall be positioned near by in the event of an emergency 3. Personnel shall be trained or informed on the basic iperation of fire extinguishers |

| Cuts, Abrasions and Burns to Hands and Fingers | 1. This is all too common occurrence when freshly cut, sharp, or hot materials are handle without the correct PPE | 1. All waste materials shall be disposed of in the scrap bins provided

2. Gloves shall be worn handling materials 3. Operators shall mark ‘Freshly Cut’ plate, etc. with the words ‘HOT’ to highlight the hazard 4. All cuts, abrasions and burns shall be treated immediately to prevent infection |

| Back Injuries Muscular Strains and Fractures etc. | 1. Can ocur if good housekeeping is not maintained areound the profile cutters | 1. Waste materials shall be disposed off on a daily basis

2. Items shall be stacked and/or stored in a tidy manner and away from access/egress routes |

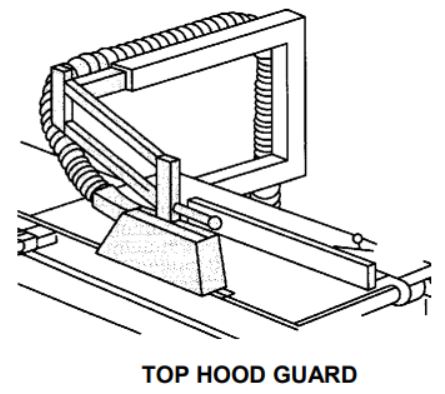

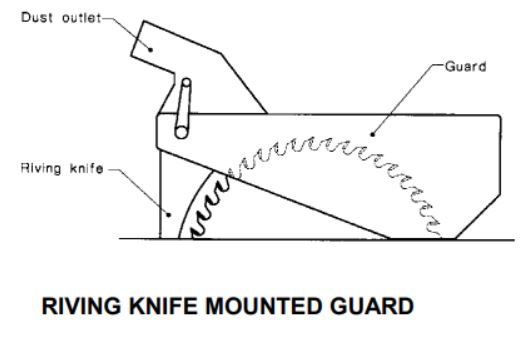

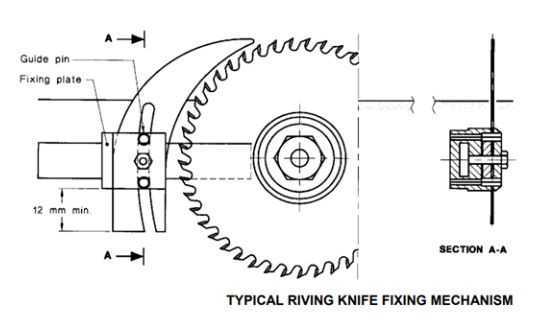

쉽게 이미지를 떠올린다면, 둥근톱기계를 생각하면 좋을 듯 싶습니다.

Bench Type의 Cutters!!!! 위 JSA 에 더 많은 위험요인을 생각할 수 있을겁니다.

추가 보완 자료는 아래를 다운로드 해보세요. 더 자세한 내용을 찾아보실 수 있을 겁니다.

You can find additional information as below site to download.

Thank you