52. Working in Confined Spaces

What are some common hazards in a confined space?

- Hazardous gases and vapor such as carbon monoxide, carbon dioxide, Freon, hydrogen sulfide, welding gases, ammonia etc.

- Asphyxiation due to limited oxygen.

- Combustible dusts.

- Flammable liquid or gases.

- Explosion.

- Engulfment.

- Becoming trapped.

- Fall hazards.

∴

∴

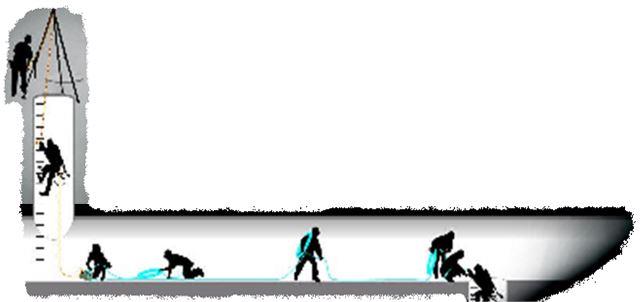

It can be any space of an enclosed nature where there is a risk of death or serious injury from hazardous substances or dangerous conditions (eg lack of oxygen). Some confined spaces are fairly easy to identify, eg enclosures with limited openings:

- storage tanks;

- silos;

- reaction vessels;

- enclosed drains;

- sewers.

Others may be less obvious, but can be equally dangerous, for example:

- open-topped chambers;

- vats;

- combustion chambers in furnaces etc;

- ductwork;

- unventilated or poorly ventilated rooms.

It is not possible to provide a comprehensive list of confined spaces. Some places may become confined spaces when work is carried out, or during their construction, fabrication or subsequent modification.

| Hazard Category | Hazards | Controls |

| Inadequate Access/Egress | 1. Personnel can become seriously injured if adequate access/egress is not provided and maintained at all times either through falls and/or by prolonged escape time in the event of an emergency. | 1. Supervisors shall ensure adequate access equipment is provided at all times.

2. Supervisors shall assess each situation individually and implement a suitable means of access/egress (i.e. scaffold, ladders, etc.) |

| Over Exposure – Inhalation | 1. Can occur if adequate ventilation/extraction is not maintained at all times. | 1. Exposure shall be reduced to well below the occupational exposure limits by using suitable extraction and/or ventilation.

2. Respiratory protective equipment (RPE) shall be worn by personnel working in confined spaces (i.e. respiratory mask or breathing apparatus) |

| Fire and/or Explosion | 1. Can occur if ignition sources (welding tongs/burning torches) are used inside tanks, chambers and/or pits which have previously contained flammable liquids/ gases and/or dusts. | 1. Atmospheric checks shall be carried out to ensure vapors and gases, etc. are well below their potentially explosive limits before allowing any work to commence.

2. Suitable extraction shall be used during the work process to extract any vapors and/or gases which may enter the area while the work is in progress. 3. Suitable monitoring equipment shall be used to continuosly measure the atmosphere for any potentially haardous vapors and/or gases. |

| Emergency Procedure | 1. inadequate emergency procedures can result in serious injury to personnel. | 1. Emergency procedures shall be implemented relevant to designated escape routes, fire fighting equipment and/or emergency first aid requirements.

2. Supervisors shall ensure that all personnel are aware of any procedures. Practice drills shall be utilized to ensure that emergency procedures are adequate. 3. A permit to work is required for any activity requiring a person to enter a confined space. |

| Working Alone | 1. Any accidents/incidents occurring to lone workers are likely to be much more severe than others as emergency procedure would be ineffective. Extreme examples of such emergencies would be unconciousness and then death, resulting from over exposure unless the operator was found within minutes of the accident/incident. | 1.A “Safe system of work” shall be in place and a permit to work obtained prior to any work.

2. A stand-by man shall be in attendance outside of the area and shall remain in full contact with the operator and monitor the work at all times. 3. Under No circumstances shall any one person enter a confined space without a permit to work or stand-by man in attendance. 4. A lifeline shall be worn by operators when working inside vessels, etc. and held securely outside the vessel. The operator shall always be in full contact with the stand-by man |

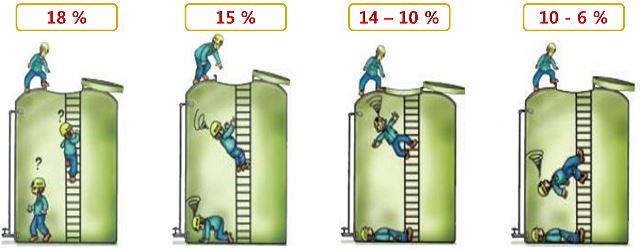

사망사고 발생률이 높은 위험작업 입니다.

혼자 작업하는 일은 절대 없도록 하고, Permit을 이용하여 모든 작업관리가 필요하며, 산소농도측정/유해가스 등의 유무를 사전 점검하여야 합니다.

밀폐공간작업!!

사고가 발생하더라도 즉시 행동하는 것은 멈추고, 전문 구조장비를 갖춘 후 구조활동이 필요합니다.

우리 곁에는 119가 있죠!!

밀폐공간 내 사람이 쓰러져 있다면, 절대 단독(혼자) 구출하기 위해 들어가지말고,

최우선으로 주변에 알려야만 합니다.

밀폐공간작업에 대하여 많은 자료가 있으니, 좀 더 찾아보시길 바랍니다.

감사합니다.