Crane & Lifting

[Contents]

[General]

▶ All lifting devices and every part thereof must be in good mechanical operating condition, free from defect

▶ Lifting devices are properly inspected, maintained, and affixed with certifications stickers

▶ All operators must possess a valid natioinal specific license and be certified by Organization

▶ All riggers must be certified by Organization

[Lifting Equipment]

All lifting equipment used must have valid test certificate

of competency to any approved third party inspections and certification

[Crane & Lifting Equipment]

All operators carry out a daily pre-operational

inspection on all crane & lifting equipment listed

A copy of the manufacturer’s operator’s manual must be abailable

[Rigger]

- Be trained in the general principles of rigging

- Able to establish weights and judge distances, heights and clearances

- Fully understand signaling and able to give precise signals

- Rigger shall be certified by Organization

[Crane & Lift Operation]

1. All crane lifts must have a trial lift prior to the actual lift

2. Engineer must investigate the stability and bearing capacity of the soil to locate a crane

3. Before beginning any crane operation, All employees related must have a tool box meeting

4. Establish barriers and boundaries

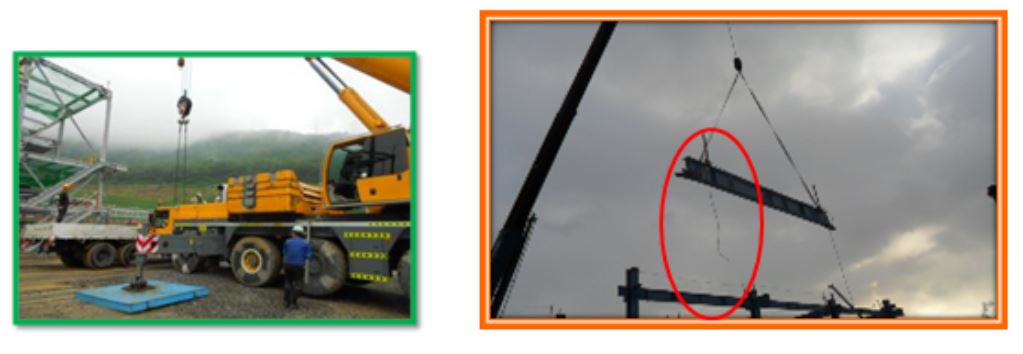

5. Suitable knot-free and defect-free lines must be used to control suspended loads

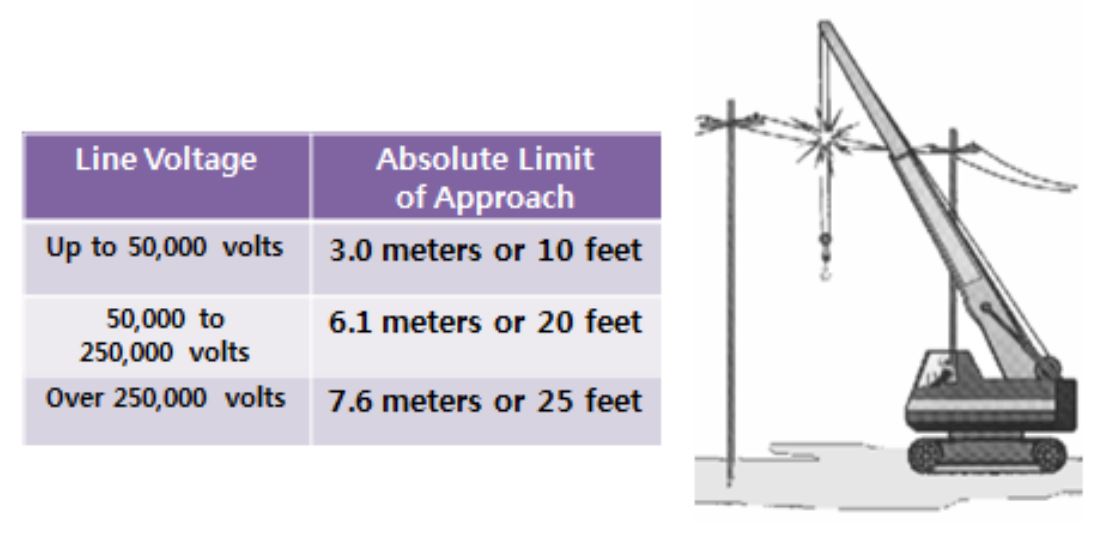

6. No crane must operate closer than 6 meters to power lines unless such line have been isolated or insulated by Organization

7. Welding or modification on load hooks and other lifting equipment is strictly forbidden

8. Any load that keeps eight-five percent(85%) of the crane’s rated load capacity or manufacturer’s specifications for that specific lift

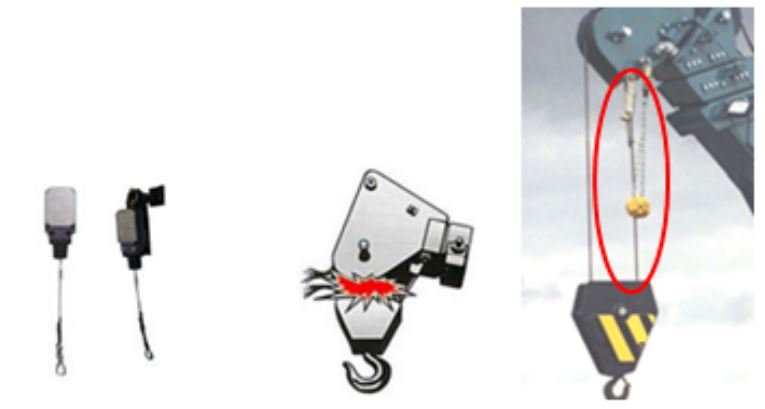

9. Must be equipped with properly working Rated Capacity Load Limiters (RCLs) and anti two-block devices or two-block damage prevention features for all points of two blocking

10. Standard must not be performed in wind speeds exceeding 9m/s

11. All cranes must have their safe working load rating clearly visible

12. When outriggers are used, They shall be extended or deployed according to the crane load rating chart specifications

13. Crane windows must be clean all times during the work

14. Use of any mobile phone function is strictly prohibited during operations

15. The crane operator must not leave the controls at any time while a load is attached

[Working near Power-lines]

Any crane working near energized powr-lines

[Critical Lift]

- Any lift above 40 tons

- Any load that exceed eighty-five percent (85%) of the crane’s rated load capacity

- Any crane lifts with explosion/ fire/ high heat hazards

- Any crane working near energized power lines

- All cranes working around hydrocarbons and pressurized piping areas

- All cranes working around populated/ traffic areas

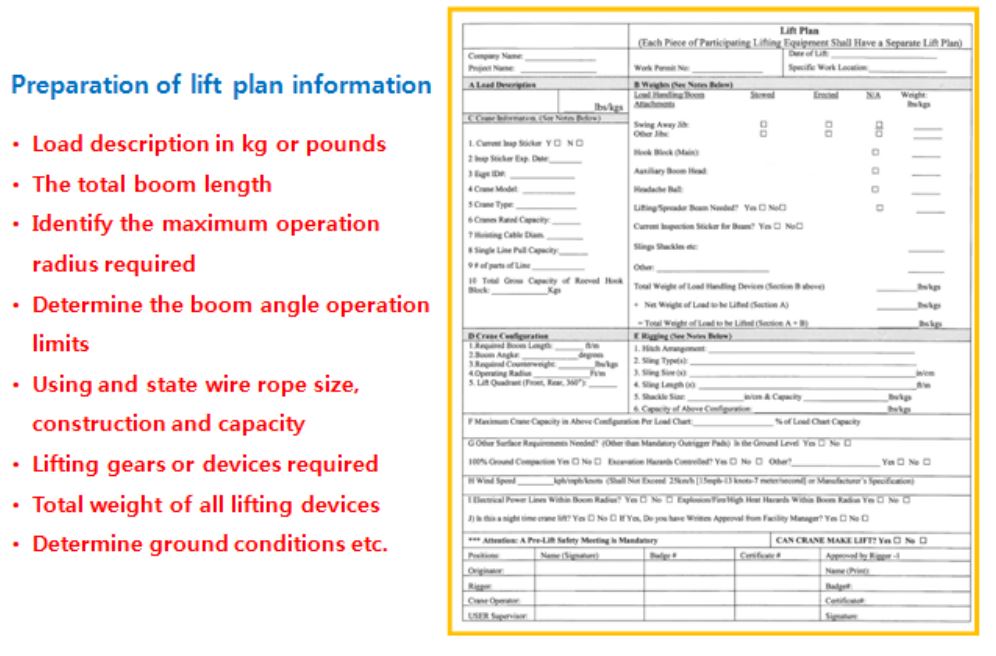

[Critical Lift Plan]

All critical lifts require an approved Lift Plan

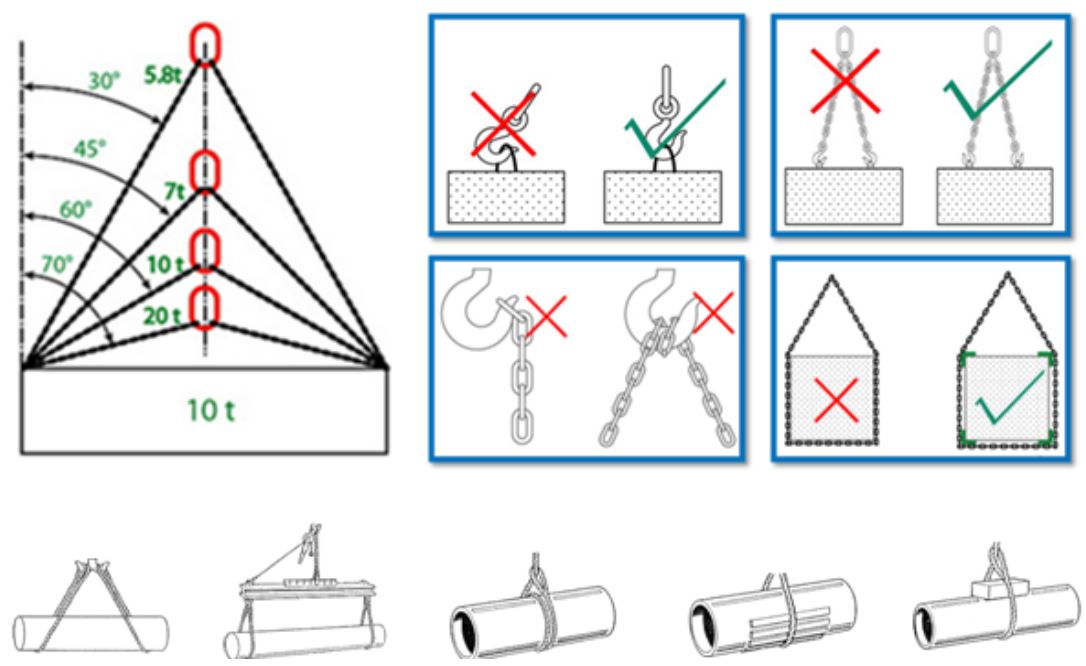

[Improper Load Case]

[Lifting Gears & Devices]

- Slings and other lifting gears must be constructed according to a recognized standard

- The safe working load of lifting device should never be exceeded

- Before use all new gears and devices should be subjected to a proof load test by the manufacturer and certified

- Riggers must not use lifting gear unless the safe working load is clearly visible

- All lifting gears & devices must be inspected at least every quarter

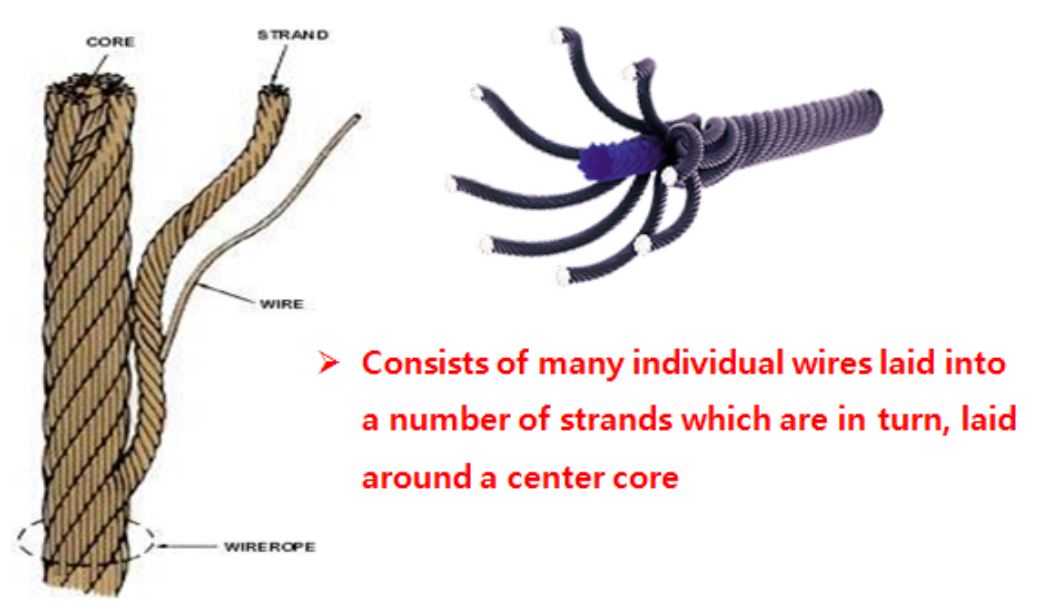

[Wire Rope Sling]

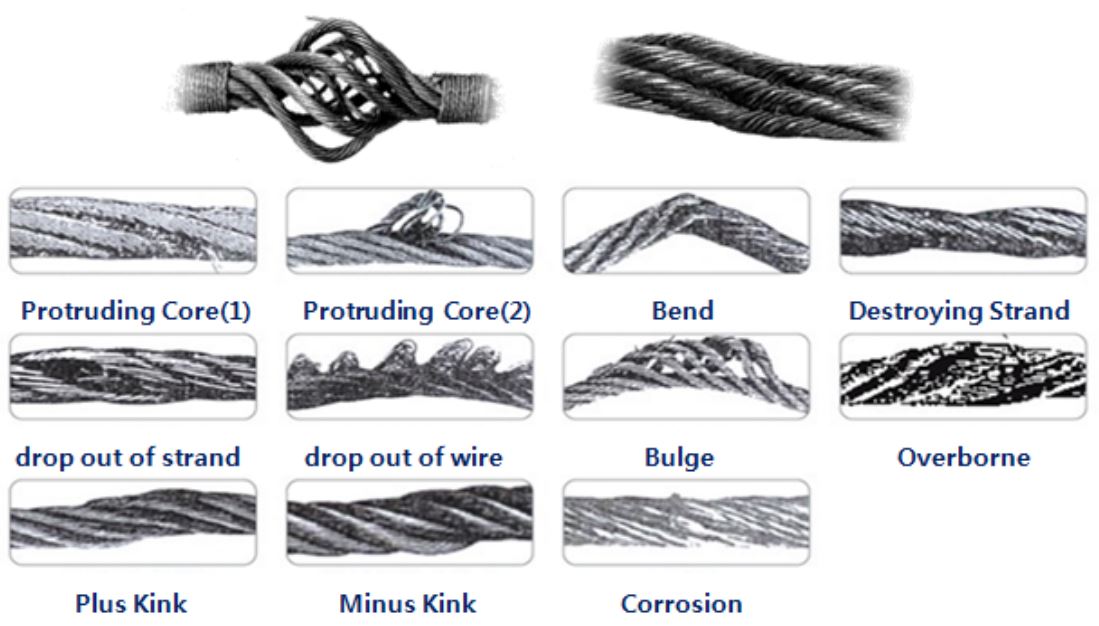

All wire rope slings must be manufactured, inspected, and load tested by a recognized manufacturer with SWL (Safe Working Load)

– Damaged wire rope sling must be destroyed at the site

– All employees comply with Color Coding procedure

[Chain Sling]

- Damaged chains must be returned to the manufacturer for repair or destroyed

- All chain is not rated the same

- Chain must have a capacity tag attached to it

- Chains must be inspected daily before use

- Ensure the chain is flexible, free from twist, knot or kink

[Chain Slings]

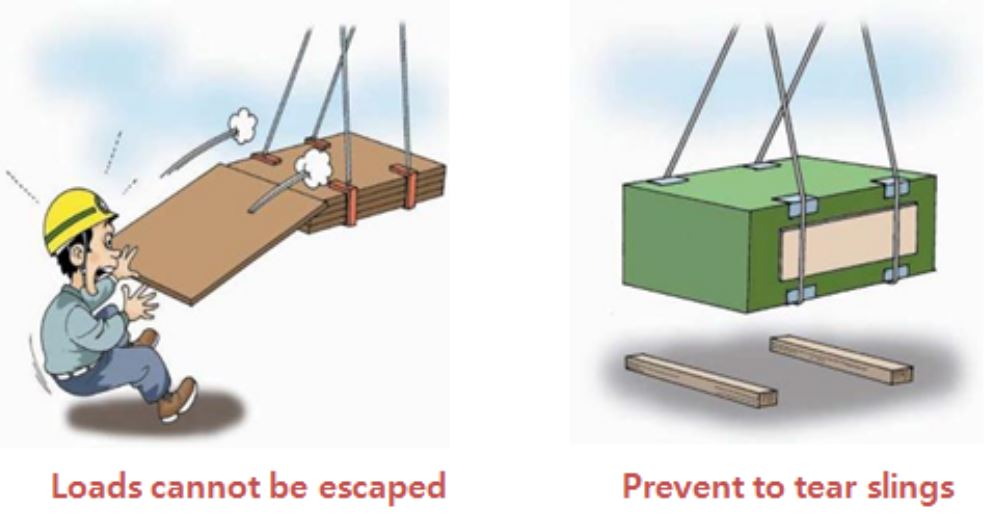

* Rigging Protectioni from Cutting or Slipping

[Synthetic Slings]

- Sling capacity varies from manufacturer to manufacturer

- Rigger must look at Capacity tag to determine safe lifting

- If the tag is not readable or is missing, Do not use it!

- Use softeners or padding on corners

- All slings must be inspected daily before use it

- Never store slings on the ground or floor and in direct sunlight

- Never store slings near atnospheric or liquid chemicals and in an area where they can be mechnically damanged

[Synthetic Slings]

Hooks must be fitted with a safety latch on the hook opening or the hook must be designed

so that the slings cannot be escaped

[Spreader Bars]

- Spreader bars must permanently identified with the safe working load, manufacturer’s name and serial number

- All speader bars must be manufactured, tested, and inspected

[Shackles]

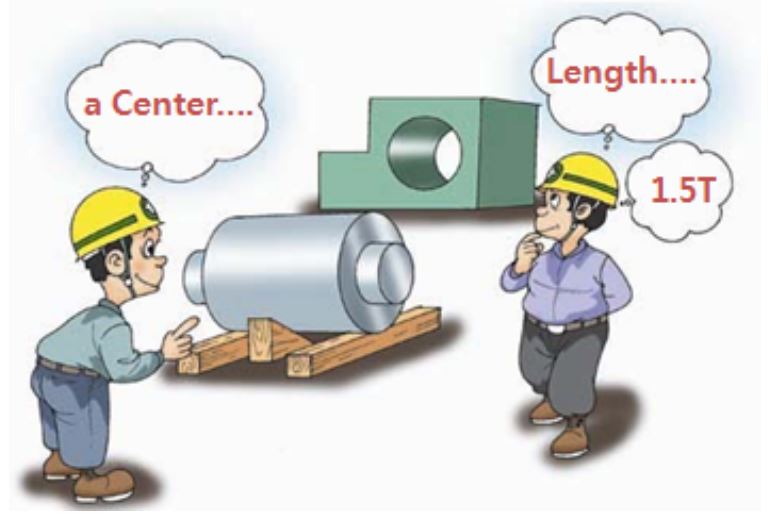

[Example]

▶ Recognize load description & Safety equipment (=device) before use it

▶ Judge a center of loads & load’s information such as length, weight etc.

▶ Perform to select the most safety method of lifting

- Hoist to be used

- State wire rope size, construction and capacity

- Identify the item, quantity required etc.

- Fixtures must be adequately kept

- Loads fix a thing down

- Damaged sling must be immediately removed form service, cut or destroyed

- Fixtures must be adequately kept

- Loads fix a thing down

- Damaged sling must be immediately removed from service, cut or destroyed

[Closing]