18. Hydrotest

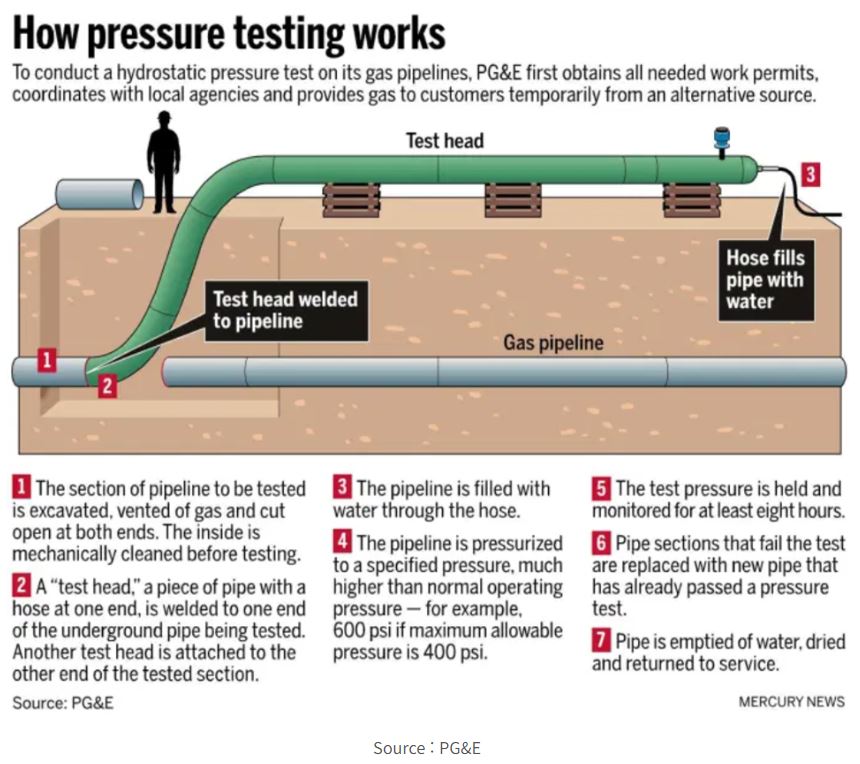

Hydrotest is a way of checking the integrity of pressure vessels, pipelines, cylinders, boilers, storage tanks as well as fuel tanks. With the help of this test, pressure tightness, strength and any leakages are checked.

Hydrotest involves a test which is performed with the help of water (which is why this test is called hydro) passed through the pipelines or tanks or any fuel carrying vessels in order to inspect any leakages in the material assembly.

Hydrotest is one of the most common methods used for testing the pressure vessels, pipelines, tanks, for any leakages and pressurization integrity of the system.

∴

∴

| Hazard Category | Hazards | Controls |

| Water Freeze | 1. Can occur when tempertatures drop below 0 ℃. Water freezing can also put additional stress on pipe work and plant, as well as the testing equipment. | 1. Supervisors shall ensure that hydrotesting is not carried out where there is a risk of water freeze.

2. The temperature shall be monitored to ensure that it does not fall below freezing point. |

| Hose Breakage During Testing | 1. Although hydrotesting is normally associated with relatively low pressures, accidents can still occur by the falure of hoses and/or connectors. |

1. Supervisors shall ensure that all equipment being used complies with all relevant ACOP(Approved Code of Practice)’s and safety standards and are certified for use.

2. Hoses shall be inspected on a routine basis to check for |

| Inadequate Testing Procedures | 1. Accidents can occur if a “safe system of work” has not been implemented prior to testing. | 1. Only tarined personnel shall be involved in testing procedures.

2. A safe system of work shall be implemented for the testing operation and personnel advice of the system prior to work commencement, i.e. at “TBT” stage. 3. Personnel shall ensure that there are no conflicting activities going on during hydrotesting stage, Which could have a direct impact on the testing operation. 4. The test area shall be barriered off and signs erected to warn and prevent access to other personnel. |

| Tripping Hazards from Hoses | 1. Can occur when hose, etc. are trailed across access/egress routes. |

1. Personnel shall ensure that all hoses have been routed in a safe menner and are suitable protected against whiplash should connections fail. 2. Any hoses routed across access/egress ways shall be protected using a scaffold board either side of the hose. 3. A sign or barrier tape shall be used to highlight the hazard. |

∴

위 그림설명을 보시면 이해에 도움이 될 것 입니다.

수압시험으로 Spool 이나 Pipeline, Tank 등등 사용 전 검사입니다.

수압시험에 사용되는 장비/기기/연결부 등은 사전 점검이 필수이며, 필요에 따라 수압시험 장비/기기에 대해서는 3rd party Certificate 또는 비파괴검사 검사증 제출을 요구하셔야 합니다.

Hydrotest 및 Pneumatic test 는 안전거리 확보가 필수적입니다.

테스트가 일시적으로 단시간에 수행이 아니기 때문에, 장시간 관계자 외 접근금지 할 수 있도록 바리케이트 또는 위험표지판으로 안전거리를 확보하시기 바랍니다.

∴

∴

Download Link : Pressure Testing Safe Distance

∴

∴

첨부파일은 Safety Distance 계산값 Sheet입니다.

현장에서 확인 결과, 3rd party에서 제공하는 Manual 과 비교했을때 차이는 있었습니다.

혹시 3rd party에서 제공하는 Manual값이 없다면 참고용으로 활용하시면 좋을 듯 싶습니다.

태풍이 지나가서 일부 지역 태풍피해가 발생된 요즘입니다.

공사현장도 더욱 주의를 갖고 점검하시길 바랍니다.

감사합니다.